Cyber Security in Aviation: Supply chain vulnerabilities and system updates and patch management

Stay in the loop

Supply chain vulnerabilities

Your supply chain is only as strong as its weakest link. In aviation, we all know how one delayed part or unchecked supplier can ground an aircraft. The same principle applies in cybersecurity.

Supply chain vulnerabilities are when attackers target third-party vendors, contractors, or partners – knowing they might not have the same level of defences as you do. Once inside a supplier’s system, they can pivot into yours, often with trusted credentials or software updates that look legitimate.

Think about how much trust flows through aviation supply chains:

- ERP integrations that connect MROs, airlines, and suppliers.

- Shared portals for inventory and procurement.

- Contractors with physical and digital access to airport or airline systems.

- If one node in the chain is compromised, the ripple effect can disrupt fleets, operations, and even safety-critical systems.

Real-world parallels: just as a counterfeit part can enter the chain and threaten aircraft safety, malicious code or stolen credentials from a vendor can compromise your systems.

Practical ways to secure your aviation supply chain:

- Vet your suppliers – cyber security should be part of the procurement checklist. Ask about patching policies, MFA, incident response, and certifications (ISO 27001, Cyber Essentials, etc.).

- Limit access – don’t give vendors blanket permissions. Apply the principle of least privilege: only the data and systems they absolutely need.

- Segment and monitor integrations – ERP and procurement platforms should be watched closely. Treat third-party connections like external aircraft arrivals: inspect and clear them before they enter the gate.

- Contracts with teeth – make cybersecurity standards and reporting obligations part of your agreements. If they suffer a breach, you should know quickly.

- Test and audit – include vendors in security assessments, penetration testing, and audits. If they’re part of your digital perimeter, they’re part of your risk surface.

- Build resilience, not just compliance – regulations help, but operational resilience comes from rehearsed plans, backup strategies, and clear escalation channels when a supplier is hit.

In aviation, a grounded aircraft doesn’t just affect one airline – it impacts schedules, airports, crews, and passengers. In cyber security, a compromised supplier can cascade disruption across the industry.

That’s why strong supply chain security isn’t optional – it’s a core part of keeping operations flying smoothly.

System updates and patch management

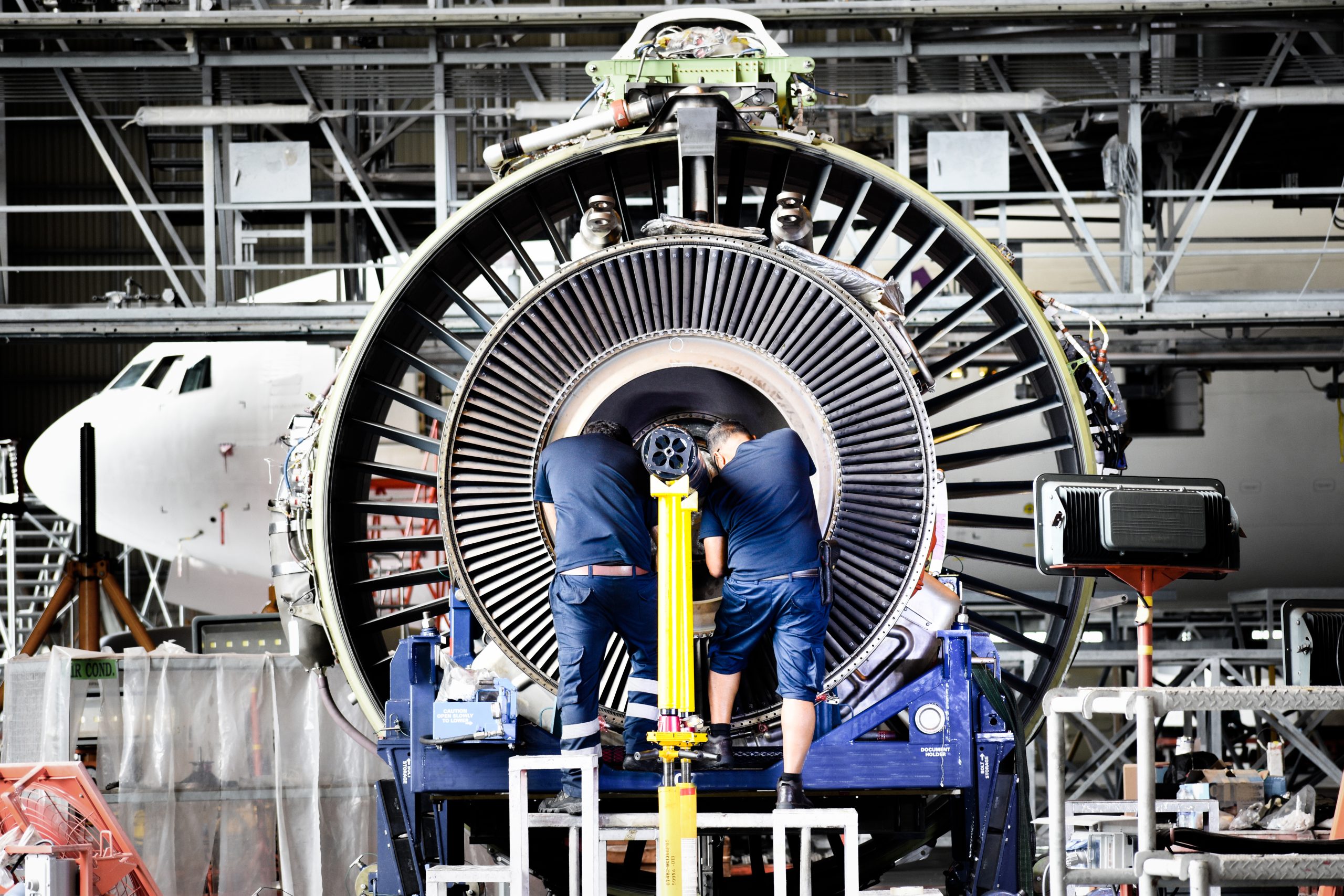

No aircraft leaves the ground without passing scheduled maintenance checks. Pilots, engineers and operators all know the risks of ignoring small faults – they compound into big failures.

The same applies in cyber security. System updates and patch management are your digital “scheduled maintenance.” Skip them, and you’re flying with hidden faults that attackers are waiting to exploit.

Outdated software is one of the most common entry points for cyberattacks. Hackers don’t need to invent clever new techniques when they can just use known vulnerabilities. In fact, many major breaches worldwide have been traced back to unpatched systems.

Think about it this way:

Would you fly with overdue maintenance tasks on your aircraft?

Would you skip inspections to save a few hours?

Then why delay patching IT systems that protect sensitive operations and data?

Practical patching and update principles for aviation businesses:

- Automate where possible – enable automatic updates for operating systems, applications, and security tools. Manual patching always risks delays.

- Schedule regular “maintenance windows” – just like scheduled aircraft checks, define clear times for system updates, with contingency plans for downtime.

- Prioritise critical patches – not all updates carry the same risk. Prioritise those fixing actively exploited vulnerabilities (often tagged as “zero-day” or “critical”).

- Maintain an inventory – you can’t patch what you don’t know exists. Keep a current list of all systems, devices, and applications across your business and supply chain connections.

- Test before rollout – especially in aviation-critical systems, test patches in a safe environment before deploying fleet-wide. Like a service bulletin, you want to validate impact before release.

Join us

For Airlines, Distributors and

Repair Centres